Product Suite

Tech Tailor’s dynamic software suite:

- Pattern Generator

- Marker Generator

- Cut File Generator

- Dynamic Runsheet Generator

1. Pattern Generator

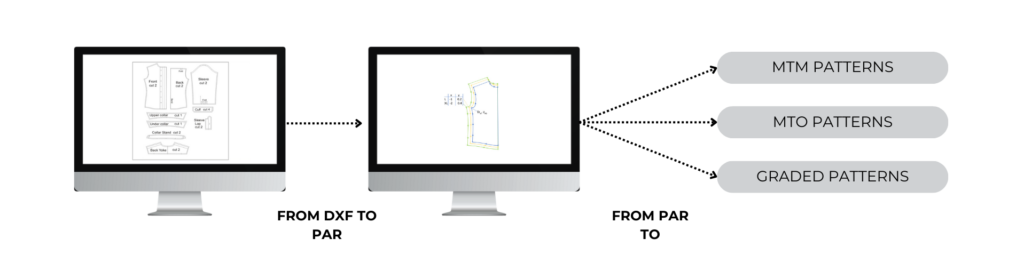

TT software generates patterns in real time. Tech Tailors developed its own dynamic file format: .par to ensure maximum flexibility on both the input and output side. TT’s pattern engines can import a standard DXF file, no extra handling required from the brand or manufacturer. Their software then converts that DXF file to a parametric pattern that’s easy to edit and export to whatever file type is required by the manufacturer. Whether it’s for MTM, MTO and/or bulk production.

1. MTM engine for MTM production

Real time MTM pattern generation, tailor to everyone, in every demographic. Our proprietary MTM algorithm creates patterns for people of every shape and size. Whether your customer is petite, tall, curvy, athletic or plus size.

2. MTO engine for MTO production

Real time MTO pattern generation for standard sizes with optional customisation such as pockets, hem lengths, sleeve length and even hammer loops.

3. Advanced Grading engine for Bulk production

Real time graded pattern generation for bulk production. Easily adjust existing patterns for:

- Different batch shrinkage

- Different batch stretch factor

- Design tweaks

- Expanded size range

- New grading rules for new demographics

2. Marker Generator

Minimise cutting waste with single and mixed markers created in a fraction of the current marker generation time.

1. Single Markers in Real Time

For MTM and MTO, TT software generates single markers accounting for:

- Grain lines

- Shrinkage

- Minimal cutting waste

2. Mixed Markers (beta) in Minutes

For (small) batch production, accounting for:

- Grain lines

- Shrinkage

- Minimal cutting waste depending on run time

3. Cut File Generator

TT’s software exports the marker in a factory specific cut file format, which means the fabric for the order can be cut immediately, without any manual interference. Resulting in:

Send the order to whichever factory has:

The fabric in stock

2. Maximum control

By sending a cut file, there is no manual interference needed on the factory floor, ensuring that the pattern will be cut according to the brand’s and or customer’s specifications.

2. Shorter lead times

By sending a cut file, there is no need to manually convert the DXF file to the factory specific cut file. This saves about 30 minutes of labour.

4. Dynamic Runsheet Generator

TT’s software can create dynamic runsheets for MTM and MTO orders, to ensure:

- Clear sewing instructions

- Quality control with final garment measurements